Welcome

About us

Innovativ • High speed action • Intelligent

We are a high-performance, medium-sized company with approximately 300 employees.

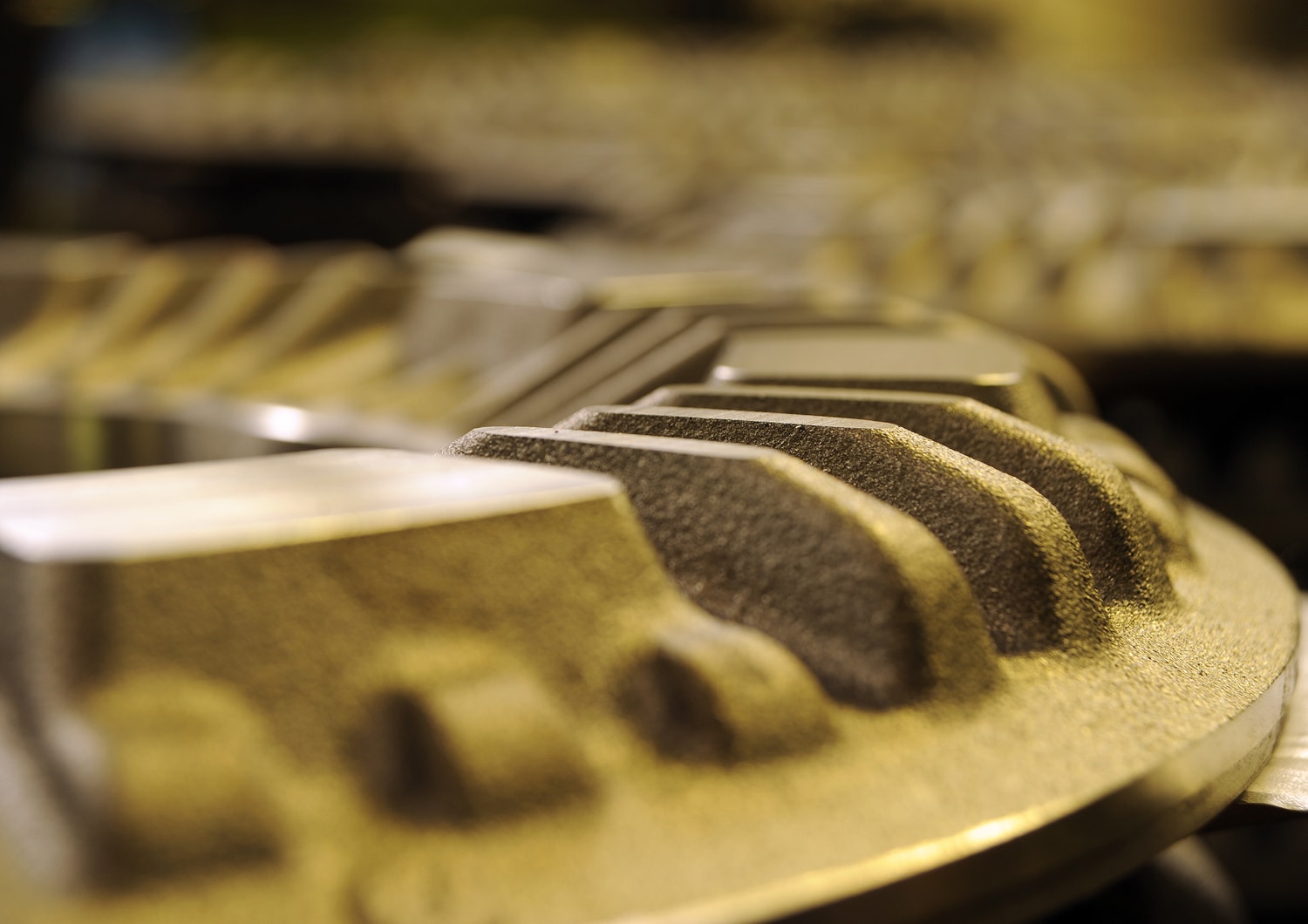

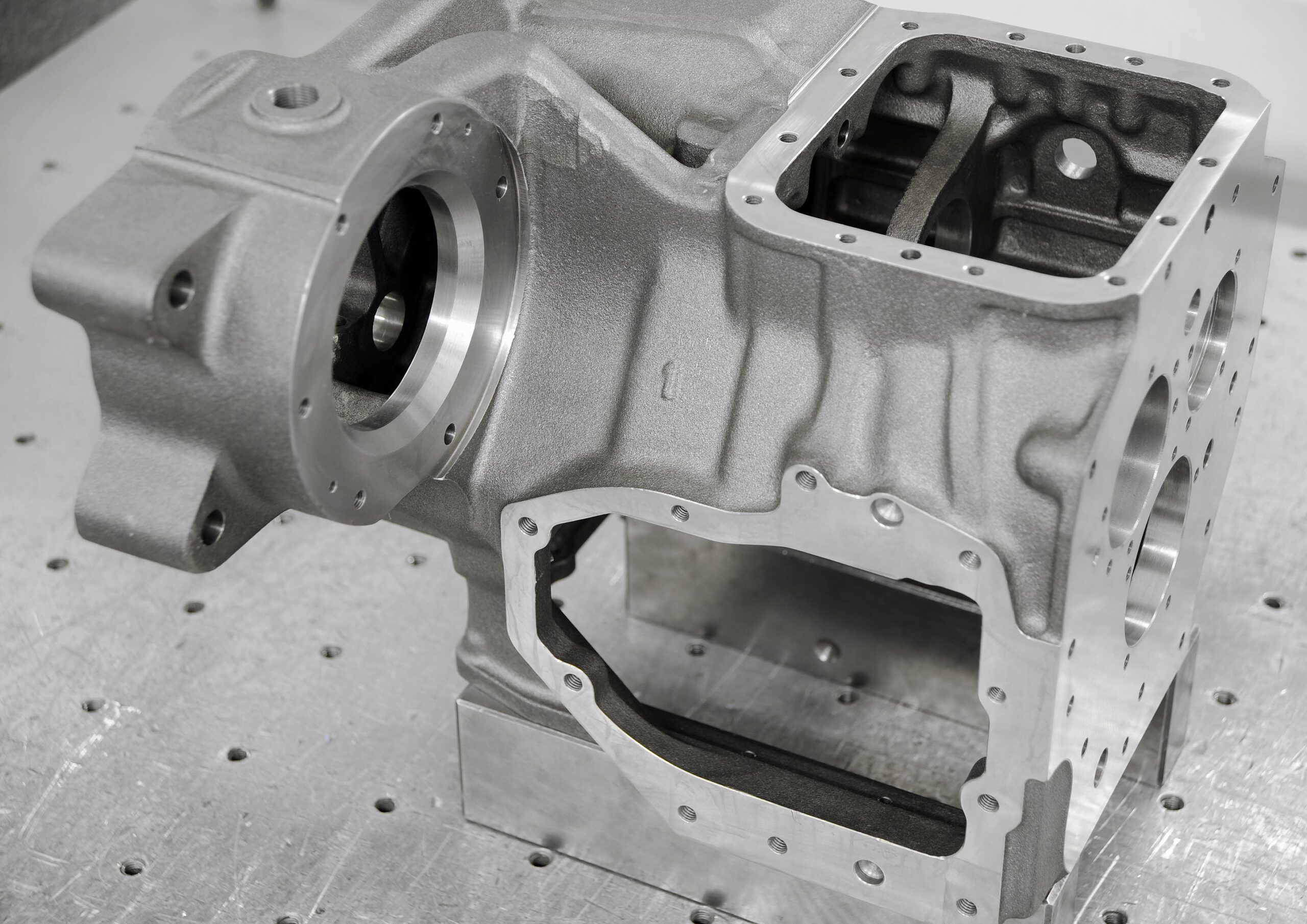

We specialize in the development, engineering and production of ready-to-install components made of grey, vermicular and spheroidal graphite cast iron.

On modern, flexible processing lines we produce – amongst other things – housings, axles, flywheels, brake discs and oil sumps.

With both self-manufactured products and bought-in parts we assemble ready-to-install system components for original equipment manufacturers in Europe, USA and Japan.

Image Film

Engineering

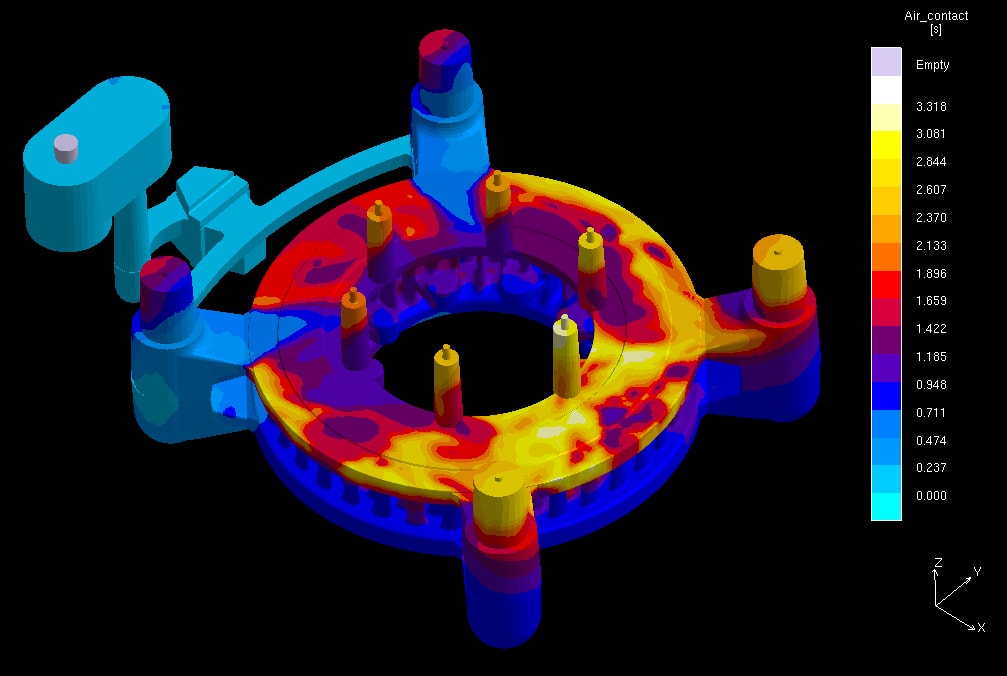

As a result of the close cooperation between our customers and our specialists in the foundry and Mechanical Processing Department, we are in a position to offer optimum solutions for each component with respect to quality and costs. Our Engineering Departments are supported in this by state-of-the-art construction design-, CNC- and simulation-software.

A useful tool for your own research on the best possible casting material is the BDG Casting Adviser. After entering your required parameters (eg, hardness, elongation, tensile strength) you will get a selection of the possible casting materials. Entering a casting material you will get spent on these all parameters.

Link to Casting Adviser

Foundry

The strategic cooperation with our customers, design consulting, simultaneous engineering, model and tool development, as well as prototype production up to series production readinesss are a strong support for the efficiency and the quality level in the production of castings.

Our Engineering Department is equipped with correspondingly high-performance software for this purpose.

Moulding box dimensions

1050 x 780 x 300 / 250

1400 x 850 x 500 / 500

Production

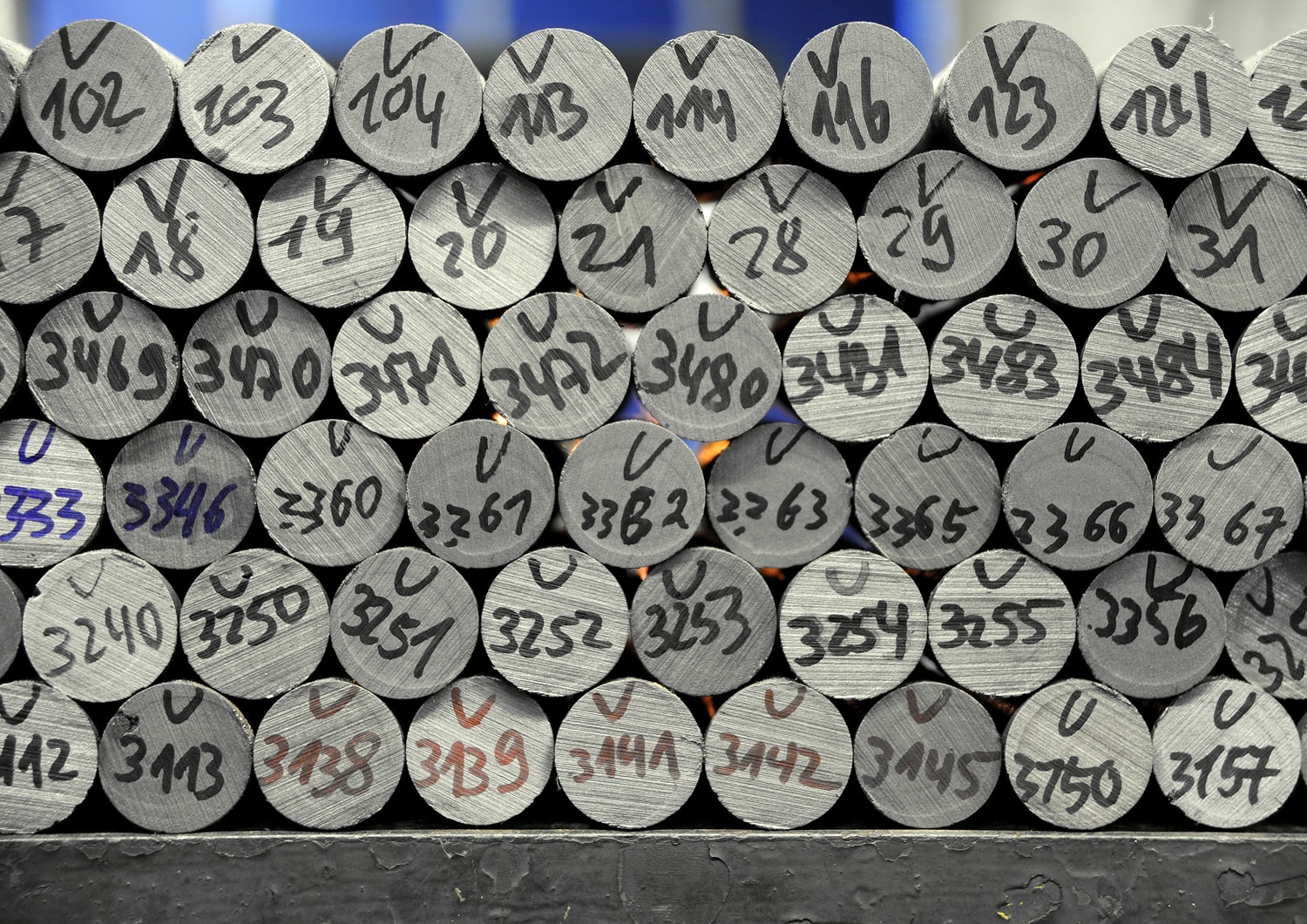

Grey cast iron GG 15 – GG 35 und GG alloyed

Spheroidal graphite cast iron GGG 40 – GGG 70 und GGG alloyed

Vermicular graphite GGV

Unit weights

from 20 to 520 kg, shaped machines

Production level

25.000 t/year

Link to Machinery & Equipment

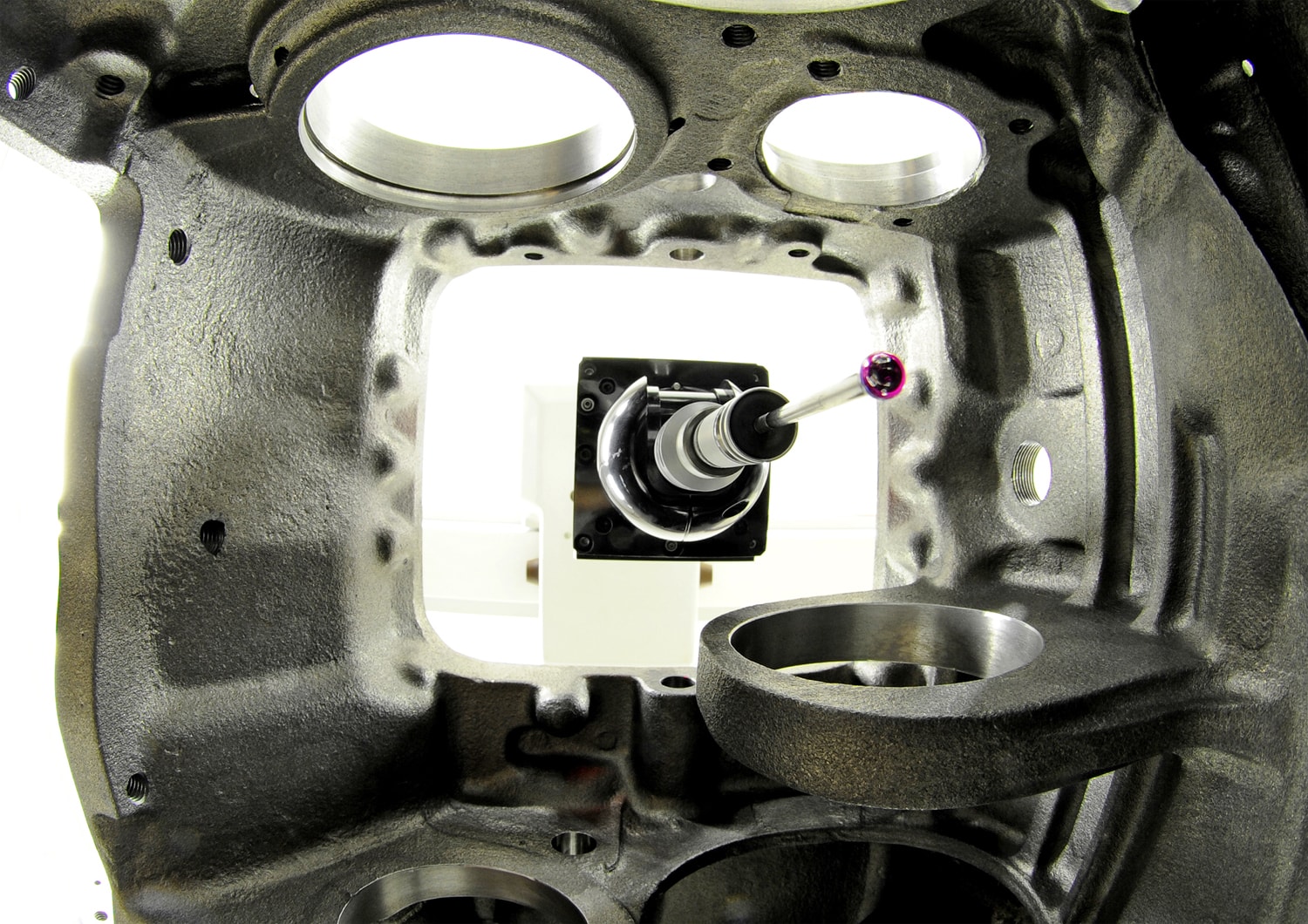

Mechanical Processing

In the machine shop we produce and finish in particular flywheels, brake and axle parts, oil sumps, clutch and gearbox housings with the highest levels of precision.

For the manufacture of small, medium-sized and large production series we use state-of-the-art CNC-controlled individual machines, machining centres, special machines, transfer lines and highly automated, flexible manufacturing systems.

Link zu Maschinery & Equipment

Assembly

Supported by our automated PPS system, we take the responsibility for the entire logistics process required for supplying our customers with fully assembled products.

The integration of casting, priming/painting and mechanical processing into an optimised and controlled process enables the assembly of components which we both have produced ourselves and bought-in parts as well to form a ready-to-use product.

As a result of this process our customers can concentrate fully on their core competencies without being exposed to the daily stress of having to solve logistical problems.

Quality Assurance

Supported by state-of-the-art measurement technology, our quality management system guarantees compliance with the agreed standards from the customer enquiry upto the shipping of the ready to use products.

Modern quality management methods such as the continuous improvement process combined with a highly motivated workforce form the basis for achieving our zero-fault target.

We are one of the few German iron foundry companies which can currently show that it uses a management system which is certified according to TS 16949 (Quality Management including ISO 9001) , ISO 14001 (Environmental Management) and ISO 50001 (Energy Management) as well.

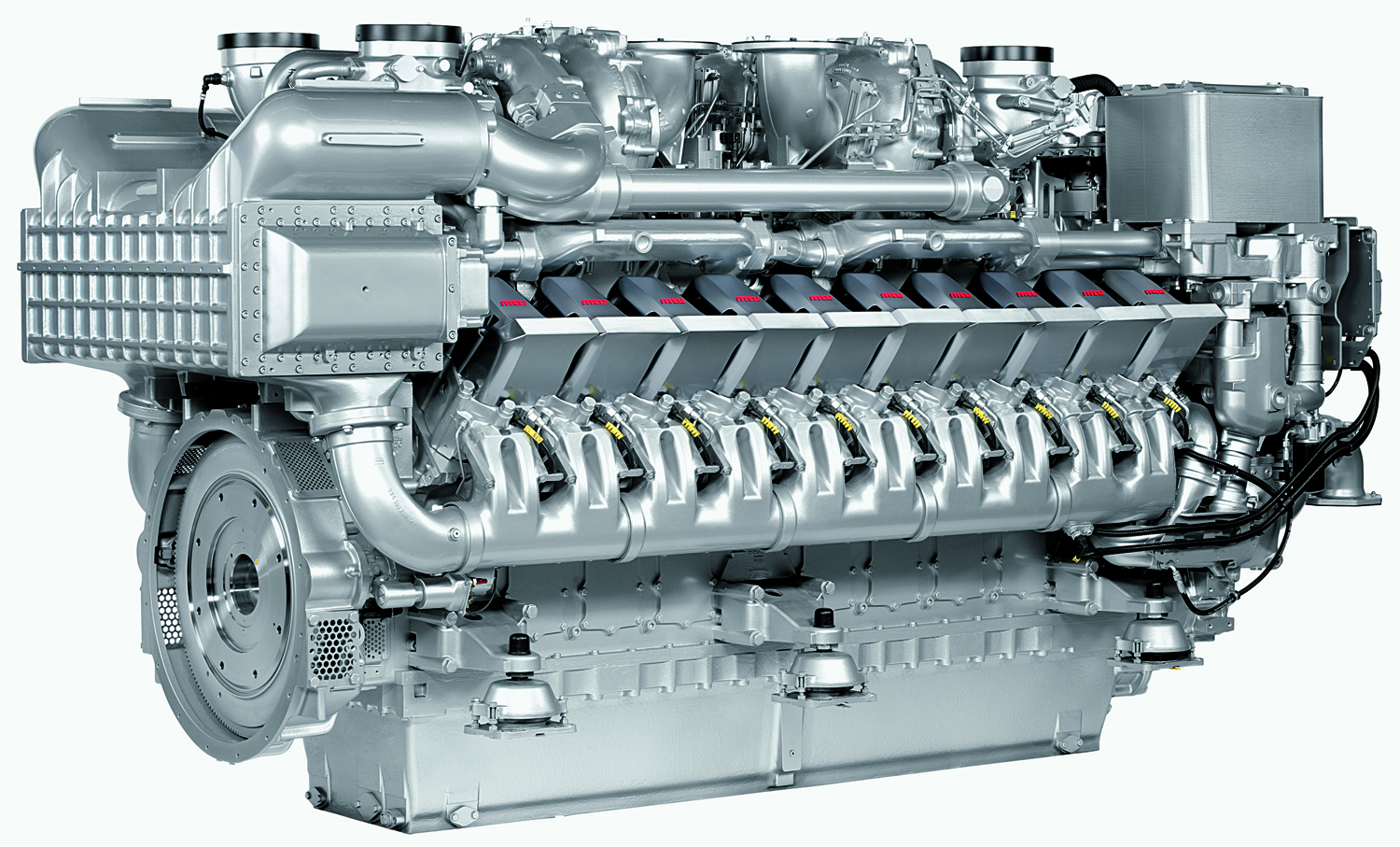

Furthermore, we have ship and train service Approvals of all the major corporations.

Link zu Certificates

Logistics

Characterised by our outstanding customer focus, supported by our own not inconsiderable technical manufacturing capabilities, as well as an excellently conceived network of reliable subcontractors, we offer our customers an extremely flexible response to their constantly changing product and logistics requirements, as well as security of supply in emergencies.

Job Market

We require…

Electrician m/f

Cutting Mechanic m/f

Toolmaker m/f

motivated trainees for apprenticeships as

- Technical model maker m/f

- Cutting Mechanic m/f

- Electrician m/f

Daniel Kühn

Telefon: 0 28 74 / 39-221

Telefax: 0 28 74 / 45-198

E-mail: personal@ihi.de

Markets and Customers

With an export share of over 50% we supply renowned customers worldwide with high-quality parts in the following fields:

Sales Department

Ralf Kaiser

Stefan Schröer

Nils Albers

Lutz Eiling

Birgit Hemming

Ruth Geuting

Fabian Hamann

Peter Kovanen

Bernard Chronowski

Our sales department is looking forward to work with you.

Tel. +49 (0) 2874 39-0

E-mail: sales@ihi.de